Wood Stone Products

Shopping Cart

Your cart is empty.

Sign in

|

Home |

What is Wood Stone

|

, ISHIMORI Wind Instruments Co., Ltd. was established as ISHIMORI Wind

, ISHIMORI Wind Instruments Co., Ltd. was established as ISHIMORI Wind

Instruments Repair Shop by Zenkichi Ishimori in Nishi-Okubo (Shin-Okubo today) Shinjuku-

ku. He was a proficient craftsman of Nippon Gakki Company Limited.

inventing instruments. He invented many essential techniques

for the current instrument production and made tools and parts

for repair by hand.His refined skills were taken over by his son.

, Minoru took over the management of the company at the young age of

, Minoru took over the management of the company at the young age of

17 because of Zenkichi’s sudden sickness. Their repair skills were getting popular among

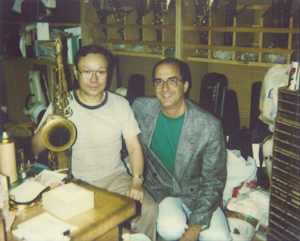

classical players by word of mouth and from the late 1950s, world-famous jazz players like

Stan Getz, Zoot Sims, Sonny Rollins and Gerry Mulligan visited the shop. ISHIMORI also

started to sell used instruments which were completely repaired. This sales method was

still not familiarized at that time and attracted a lot of players.

, ISHIMORI expanded their workshop and installed more repairing tools

, ISHIMORI expanded their workshop and installed more repairing tools

and machines, which made it possible to do the whole process only in the workshop

including polish, lacquer and overhaul. There were actually a few workshops which could

do the whole things at that time. Also they started to sell the brand new instruments

that were completely repaired and adjusted to the top condition and many distant

players came to the shop to buy those instruments.

, Tomochika Ishimori,Minoru's eldest son, entered ISHIMORI.

, Tomochika Ishimori,Minoru's eldest son, entered ISHIMORI.

, Shinji Ishimori,Minoru's second son, entered ISHIMORI.

, Shinji Ishimori,Minoru's second son, entered ISHIMORI.

, ISHIMORI moved to the Wood Stone Building that was built in Hyakunin-

, ISHIMORI moved to the Wood Stone Building that was built in Hyakunin-

cho, 2-chome, Shinjuku-ku. There were two studios to try out ISHIMORI items in the

basement, the shop on the first floor, the repair rooms on the second and third floor and

lesson studios on the fourth floor.

around this period to meet various kinds of demand about repair. The sales department

expands their line of vintage saxophones and started to carry variety of items. Also, the

greatest players like Gary Bartz, David Sanborn and Micheal Breacker held their clinic

in a basement studio.

Ishimori completed a prototype of their ligature as the first " Wood Stone" product.

prototype of Wood Stone ligature

This ligature was made thoroughly by hand. Shinji Ishimori, who was responsible

for product planning and a craftman, collected and analyzed a huge amount of data

from other brands' ligatures thoroughly from every angle and made a lot of prototypes

and tested them repeatedly. After the period of trial and error, he finally completed

the ligature, the first "Wood Stone" product. He also studied many reeds from the

world to make the Wood Stone reeds.

, ISHIMORI changed its name to "ISHIMORI Wind Instruments Co., Ltd." as

, ISHIMORI changed its name to "ISHIMORI Wind Instruments Co., Ltd." astheir business grew.

Sadao Watanabe,Minoru Ishimori,David Sanborn, Minoru Ishimori and Micheal Breacker Wood Stone Building

Shinji Ishimori, Tomochika Ishimori

and repairmen

, the ISHIMORI Building was built in Hyakunin-sho, 1-chome, Shinjuku-ku,

, the ISHIMORI Building was built in Hyakunin-sho, 1-chome, Shinjuku-ku,

which had a showroom, an event space, studios and a repair room. The showroom

carried a wider range of items and increased the line of the Wood Stone product.

In 2008, the YAS-82ZWS alto saxophone was completed by the collaboration of

YAMAHA and ISHIMORI. This saxophone has been highly appreciated by professional

and amateur players in Japan and overseas.

In 2010 October, ISHIMORI released the original tenor saxophone and many players

praise it a great deal.

Showroom staff Repairmen ISHIMORI Building

that surprises every saxophone player. A lot of saxophones including current and

vintage models are exhibited in the showcases. It is a spectacular view.

mouthpieces and of course current mouthpieces also.

Wood Stone brand was born 24 years ago starting from

manufacturing a ligature by Shinji Ishimori, the developer

and the craftsman.

He collected and analyzed a huge amount of data from

other brands’ products thoroughly from every angle and

manufactured a lot of prototypes and tested them repeatedly.

Finally, Wood Stone ligature was born as the first Wood Stone

product. Our original products include mouthpieces, reeds,

thumb rests, thumb hooks, cases, straps, cleaning kits

and so on.

We are working on inventing new products day by day.

Shinji Ishimori, the developer and the craftsman

Wasn’t it a hard work for you?

Wasn’t it a hard work for you? Yes, it was actually for me. In fact, I collected and looked into a lot of data about every kind of the famous ligatures of the past. I collected a variety of detailed data such as the length of a screw of each ligature and studied how the strength of those ligatures was enhanced. Also I collected many kinds of reeds all over the world and measured, precisely in detail, the thickness of the vamp and the tip of the reeds to study how they vibrated and how tone color changed.

Yes, it was actually for me. In fact, I collected and looked into a lot of data about every kind of the famous ligatures of the past. I collected a variety of detailed data such as the length of a screw of each ligature and studied how the strength of those ligatures was enhanced. Also I collected many kinds of reeds all over the world and measured, precisely in detail, the thickness of the vamp and the tip of the reeds to study how they vibrated and how tone color changed. Did you have anxiety about your studying and inventing a lot of products by yourself?What is your motivation to invent the Wood Stone products?

Did you have anxiety about your studying and inventing a lot of products by yourself?What is your motivation to invent the Wood Stone products? I did not feel any anxious although I started from scratch. But I rather felt excited and noticed the difficulty to make something as I manufactured. It is a lot of fun for me to make something. Making something is really interesting for me. I have never thought it was painful for me to do it. Rather I really enjoy making and trying prototypes. I am always excited to make products

I did not feel any anxious although I started from scratch. But I rather felt excited and noticed the difficulty to make something as I manufactured. It is a lot of fun for me to make something. Making something is really interesting for me. I have never thought it was painful for me to do it. Rather I really enjoy making and trying prototypes. I am always excited to make products thinking “what sound this is going to have!” I also often notice new things at this stage. Actually there have been many products I had to give up making.

Why do you stick to make a product by hand work? Why do the Wood Stone products need to be made by hand?

Why do you stick to make a product by hand work? Why do the Wood Stone products need to be made by hand? I think the product can meet my ideal only when it is made by hand. In fact, all the screws of our ligatures are hand-made. The hand-made product is not impersonal and not strictly structured like the machine product. Rather it can be flexible and we can make a flexible curve. That’s why I stick to hand working.

I think the product can meet my ideal only when it is made by hand. In fact, all the screws of our ligatures are hand-made. The hand-made product is not impersonal and not strictly structured like the machine product. Rather it can be flexible and we can make a flexible curve. That’s why I stick to hand working. What do you think while you are making a product?”

What do you think while you are making a product?” Soon after I come up with the image of a product, I start to make it. So, I think over a product when I design it rather than while making it, like when I designed the ligature, I would think of its screw strength. The ligature screw is certainly a small part but really important since it sustains even greater pressure than many people expect. So, the question was how the pressure had to be distributed and I needed to think about the ligature design at the same time. I thought over its balance. I even dreamed it. While I sleep, sometimes inspirations about new products hit me. When it happens, I always get up quickly and take a note about a product. Actually I have many products in my mind that have not been produced but still remain as images on memos in my drawer.

Soon after I come up with the image of a product, I start to make it. So, I think over a product when I design it rather than while making it, like when I designed the ligature, I would think of its screw strength. The ligature screw is certainly a small part but really important since it sustains even greater pressure than many people expect. So, the question was how the pressure had to be distributed and I needed to think about the ligature design at the same time. I thought over its balance. I even dreamed it. While I sleep, sometimes inspirations about new products hit me. When it happens, I always get up quickly and take a note about a product. Actually I have many products in my mind that have not been produced but still remain as images on memos in my drawer. What are the concept of the Wood Stone products? What is the future plan about the product development?

What are the concept of the Wood Stone products? What is the future plan about the product development?  The theory of our brand is based on the ideas like “this product would be good”

The theory of our brand is based on the ideas like “this product would be good”or “this product would be useful”. I am always producing our items with such ideas in my mind. I want our brand to meet as many needs as possible. We are going to expand a variety of our products to the world as well as in Japan.